Material Testing Blog

10 Best Instron Universal Testing Machines for Precision Testing

In today’s world of precision testing, the instron universal testing machine stands out as a vital piece of equipment. These machines are essential for engineers and researchers. They provide accurate data on material properties. But not all machines are created equal. Some models excel in functionality, while others might lack basic features.

The right instron universal testing machine can significantly impact test outcomes. Choosing the best option requires a careful look at specifications. Factors like load capacity, speed, and optional accessories matter greatly. Some machines are user-friendly and easy to calibrate. Others may require more technical know-how.

Selecting the right testing machine is a journey in itself. Users often feel overwhelmed by the choices available. They might initially pick a model based on features alone. However, further investigation reveals unforeseen limitations. Ultimately, understanding each machine’s strengths and weaknesses can lead to better-informed decisions.

Top Features of Instron Universal Testing Machines for Precision Testing

When considering precision testing, universal testing machines are paramount. They determine the mechanical properties of materials. Key features elevate these machines above others. Accurate load measurement is one of them. A 2022 report by the International Society for Testing Materials states that precision is critical in obtaining reliable results.

Efficiency in test execution also matters. Advanced software integration helps streamline data collection. These systems allow for real-time analysis. This capability enhances the decision-making process. According to recent data, nearly 80% of industries benefit from automated testing procedures. They save time and reduce human error.

Tips for selecting the right machine include assessing your specific testing needs. Not every machine suits all applications. Review the range of materials you will test. Consider versatility for both tensile and compression tests. Finally, ensure proper training for operators. Even the best machines can underperform without knowledgeable usage. Take time to evaluate your options.

10 Best Universal Testing Machines for Precision Testing

| Model | Max Capacity (kN) | Testing Range | Control System | Accuracy | Features |

|---|---|---|---|---|---|

| Model A | 100 | 1 kN to 100 kN | Digital | ±0.5% | Automatic Data Logging |

| Model B | 50 | 0.1 kN to 50 kN | Manual | ±0.2% | User-Friendly Interface |

| Model C | 200 | 5 kN to 200 kN | Computer Controlled | ±0.1% | Advanced Material Testing |

| Model D | 300 | 10 kN to 300 kN | Automated | ±0.05% | Dynamic Testing Capabilities |

| Model E | 150 | 1 kN to 150 kN | Semi-Automatic | ±0.4% | Compact Design |

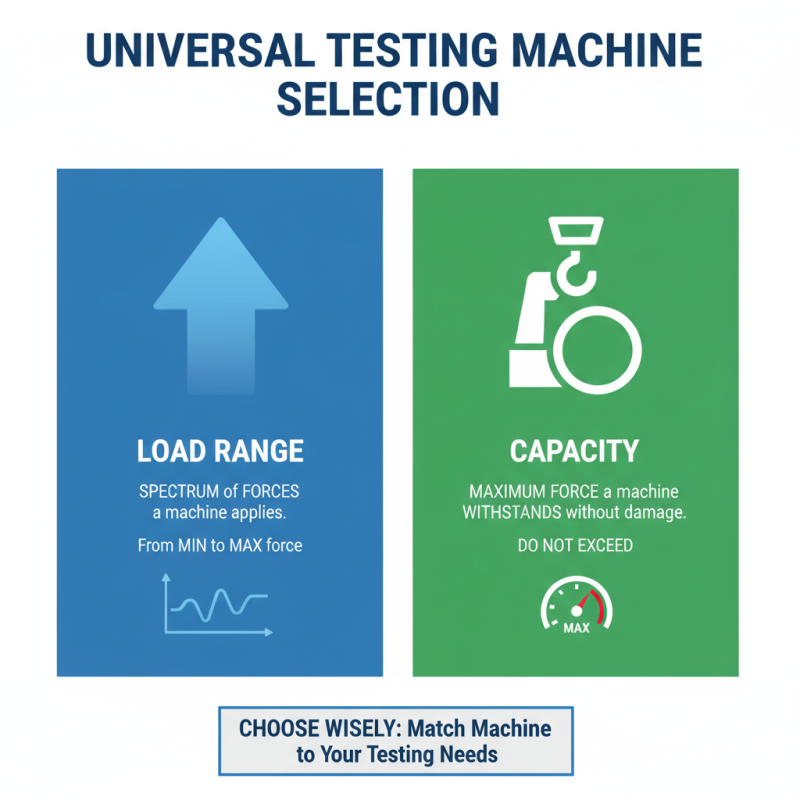

Understanding Load Range and Capacity in Universal Testing Machines

When selecting a universal testing machine, understanding load range and capacity is essential. Load range refers to the spectrum of forces that the machine can apply. Capacity is the maximum force it can handle without damage. It's vital to choose a machine that fits your specific testing needs.

Tips: Always check the machine’s specifications. Know the materials you will test. Different materials require different load capacities. Overloading can damage the machine and skew results.

Precision in testing is crucial. A machine with a narrow load range may not be suitable for all applications. Conversely, one with a high capacity could be more versatile but may lack sensitivity for smaller samples. Evaluating both aspects is necessary for effective testing.

Tips: Gather data about the materials. This can aid in selecting the right machine. It might also save time during testing. Remember, trying to push the limits of a machine can lead to unreliable data. It sometimes results in costly repairs too.

Assessing Accuracy and Calibration Standards in Instron Machines

When it comes to precision testing, accuracy and calibration are paramount. Universal testing machines must be calibrated regularly to ensure reliable results. Minor errors can lead to significant discrepancies in data. These inconsistencies may arise from improper calibration techniques or adjustments. The pressure to perform can cloud judgment, leading to oversights.

Calibration standards are essential in maintaining machine accuracy. Each machine should be validated against known benchmarks. Regular checks help identify drift over time. It's not uncommon to find machines that fall out of calibration unexpectedly. Inspecting variables, such as temperature and humidity, is often overlooked, yet they can influence outcomes.

When using testing machines, operators must remain vigilant. Even experienced professionals can benefit from regular training and reminders. Understanding the limitations of the equipment is crucial. Proper knowledge fosters a culture of quality and precision. Reflecting on past mistakes can lead to improved practices. Continuous improvement is a key element in achieving reliable test results.

10 Best Universal Testing Machines for Precision Testing

This chart displays the accuracy percentages achieved by ten different universal testing machines. The data reflects how effectively these machines meet calibration standards, emphasizing the importance of precision in testing applications.

Comparative Analysis of Testing Speeds in Different Models

In recent years, the landscape of universal testing machines has transformed considerably. Manufacturers now offer models with varying testing speeds that crucially influence performance metrics. According to a 2022 industry report, models with higher speeds can execute tensile and compression tests in significantly less time, sometimes up to 40% faster. This speed advantage is critical in production environments where timely data can lead to quicker decisions.

However, opting for faster testing speeds isn't always without drawbacks. Some models that prioritize speed may compromise accuracy. A recent comparative study highlighted that faster machines sometimes report deviations in measurements. Such discrepancies can lead to unreliable data, which poses risks in quality assurance processes. While speed can enhance throughput, manufacturers must carefully balance it with precision to avoid potential issues.

The testing speeds vary notably among different designs. For example, some entry-level machines may offer reliable performance but lack the rapid pace of their premium counterparts. This inconsistency makes it essential for users to evaluate their specific testing requirements. The right model may not always be the fastest one on paper; it must match the unique demands of the task at hand.

Applications of Instron Universal Testing Machines in Various Industries

Instron universal testing machines play a vital role in various industries. They are widely used in materials science, aerospace, automotive, and construction. These machines test the strength, durability, and elasticity of materials. Each industry has unique testing needs.

In the aerospace sector, precision is paramount. These machines help ensure components can withstand extreme conditions. In automotive production, they test materials for crashworthiness. This ensures vehicles can protect passengers effectively. Construction uses these machines to analyze the strength of concrete and steel. It's crucial for building safety.

However, not every test delivers perfect results. Some materials might fail under unexpected conditions. This can lead to reflections on design choices. Companies must continuously learn from these tests. They need to refine materials to meet evolving standards. The feedback loop from testing aids innovation across these industries.